Properties:

- Complete range of DIN & British standard cells

- Options: automatic filling system, acid circulation, level indicator & data logger

- Robust plastic housing

- Minimum maintenance

- Long lifespan

- Sharp price

Applications:

Traction batteries are mainly used in heavy industrial electrical applications such as: electric forklift trucks, electric tractors, large industrial cleaning machines, aerial platforms, …

A traction battery consists of several cells of 2V. When those cells are connected in series, you get higher voltages. A traction battery of 24 volts has 12 cells, a 48 volts battery has 24 cells, a 80 volts battery has 40 cells. To recharge a battery, the cell voltage has to be increased to above 2 volts by an external voltage source.

Traction batteries differ from starter batteries because they have been developed to provide a certain amount of energy for longer periods. As a result, traction batteries usually have a much higher capacity than starter batteries.

The different technologies

Traction cells already exist in different technologies, these are: Open Lead Acid, Low Maintenance, Pure Lead Carbon, Gel, CSM, Square and Lithium-Ion :

PzS – PzB

The most representative solution portfolio for the Material Handling Industry.

Vented lead acid battery with liquid electrolyte.

Proven tubular plate technology provides long service life and excellent reliability, utilizing premium quality materials.

1500 cycles, 80% DOD

Low Maintenance

The low maintenance solution with up to 13 weeks interval.

With special design and optimized alloys minimizes water consumption.

Best solution to optimize customer’s service cost.

1500 cycles, 80% DOD

GEL

The maintenance free valve regulated gas recombination batteries with GEL electrolyte.

Particularly suitable in the food, pharmaceutical and chemical industry.

No acid leakage and minimum gas emissions.

1250 cycles, 60% DOD

CSM

Based on CSM (Copper Stretch Metal) technology CSM batteries ensure increased performance, capacity and energy efficiency.

Suitable for operation under extreme conditions (Cold Store).

Allowing fast and opportunity charging.

>1500 cycles, 80% DOD

Square

The SQUARE Technology (square tubes) allows a larger surface area of the active material to be exposed to the electrolyte with a higher specific gravity, leading to increased power and longer operating time.

1700 cycles at 80% DOD

Pure Lead Carbon

Maintenance Free, 99,99% Pure Lead

Longer lifetime in hard conditions

Fast recharge

Exceptional PSOC performance

Opportunity charging

1200 cycles, 60% DOD

Li-Ion

The Li-Ion battery based on our vast know how and long experience for advanced applications.

The combination of fast and opportunity charging with the battery’s outstanding efficiency and charge acceptance enables multi-shift operation and an n overall 24/7 availability.

4000 cycles, 80% DOD

Total partner

Battery Supplies is your one-stop-partner for everything that has to do with traction batteries. From a new battery with all possible accessories (automatic filling system, chargers, etc.), periodic maintenance, to repairs of defective batteries.

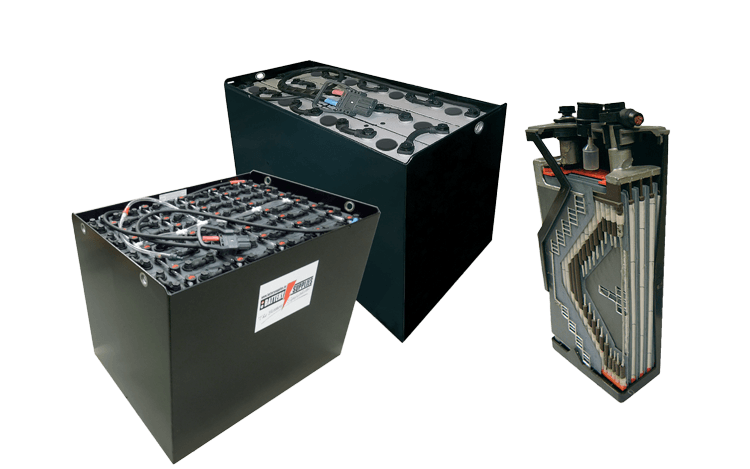

Composition of a traction battery

A traction cell is composed of positive and negative plates, there is always 1 negative plate more than the number of positive. The positive and negative plates are separated from each other by means of a micro porous separator in order to avoid mutual contact and short circuit.

The positive plate consists of a tube plate and a number of lead rods together, which are then protected as a whole by a porous material that is folded around the plate like an envelope. The space between the plates is filled with a paste of lead dioxide. The exact composition of these plates varies from manufacturer to manufacturer and is already an important part of the final quality of the cell.

The negative plate is a grid of pure lead. These plates are in a bath with electrolyte, a mixture of sulfuric acid with water.

Some important tips for longer life of your traction battery.

- Only refilling with demineralised water

- Refilling after charge

- Refilling up to the bottom side of the baskets: not higher!

- Keep the upper side of the battery dry and clean

- Use an adequate charger for battery & capacity

- Avoid intermediate charges

TIP: Acid circulation in combination with high frequency charger results in a battery with maximum usability and a minimum of maintenance!

How do I order a traction battery? We need this information from you.

We need the following information from you in order to tailor a traction battery:

- Brand and type of the forklift truck

- Voltage & Ah of the battery

- Size of the outerbox or of the elements: X x Y x H

- Options: autom. filling system, acid circulation

- Type of the battery plug

- …