De bewezen PzS-technologie met buisvormige platen in combinatie met een aangepast laadregime zorgt voor langere bijvul intervallen. De cellen zijn gefabriceerd en getest volgens EN60254-1 en IEC254-1.

Onderhoudsarm 8-serie :

- – Bijvul interval tot 8 weken

- – HF-lader (laadfactor 1,10 – 1,11)

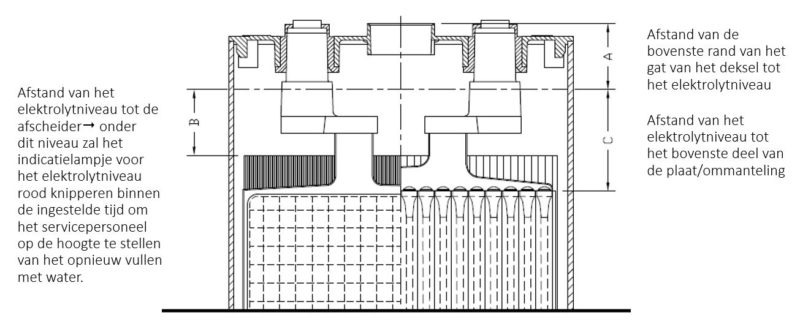

- – Electrolyte level indicator

- – Automatisch vulsysteem (optioneel, maar aanbevolen)

Onderhoudsarm 13-serie :

- – Bijvul interval tot 13 weken

- – HF-lader + Zuurcirculatiesysteem (laadfactor 1,07 – 1,08)

- – Electrolyte level indicator

- – Automatisch vulsysteem (optioneel, maar aanbevolen)

Technische kenmerken en voordelen

- Interval tussen het bijvullen van water wordt efficiënt verlengd

- Lager waterverbruik

- Weinig onderhoud en lagere operationele kosten

- Lagere laadfactor

- 50 tot 80% minder gasafgifte en ventilatie vereist

- 20 tot 30% minder laadtijd

- Kostenbesparing door een lager energieverbruik van 10 tot 20%.

- Lagere gebruikstemperaturen

- 1500 cycli @ 80% DOD

Toepassingen

Heftrucks, industriële reinigingsmachines, pallettrucks, AGV

Cel ontwerp

Kosteneffectieve oplossing

| Vergelijkingsparameters | Standaard systeem | Low maintenance |

|---|---|---|

| Batterij | zelfde niveau | kleine hogere initiële kost |

| HF lader | meestal 50Hz | standaard, hogere kost, sneller en beter laden |

| Aquafilling | optioneel | optioneel |

| Indicator elektrolytniveau | optioneel | standaard |

| Servicekosten | hoog | laag |

| Energieverbruik | hoog | energiebesparend |

| Operationele efficiëntie | standaard | hoger |

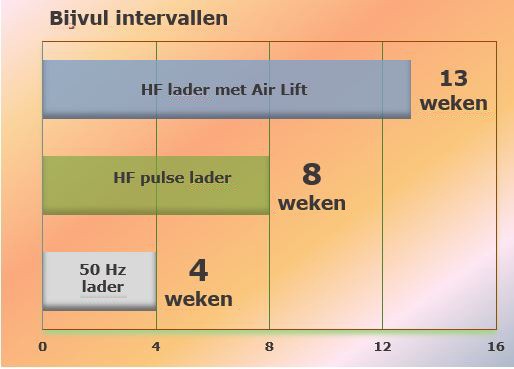

Bijvul intervallen

- De herhalingsintervallen zijn gebaseerd op 80% DoD – 5 cycli per week

- De volgende factureringsfactoren worden overwogen

- 1.2 voor de conventionele (50 Hz) oplader

- 1,10 tot 1,12 voor de HF-pulslader

- 1,07 voor de HF-oplader met behulp van het Air Lift-systeem

Beschikbare versies

| Vergelijkingsparameters | Typisch systeem | Low maintenance 4 | Low maintenance 8 | Low maintenance 13 |

|---|---|---|---|---|

| Bijvul interval | 2 weken | 4 weken | 8 weken | 13 weken |

| Lader | 50 Hz | 50 Hz | HF | HF + airlift |

| Laadfactor | 1,2 | 1,2 | 1,11 | 1,07 |

| Indicator elektrolytniveau | – | Ja | Ja | Ja |

| Aqua filling | optioneel | optioneel | optioneel | optioneel |

| Airlift | – | – | – | yes |

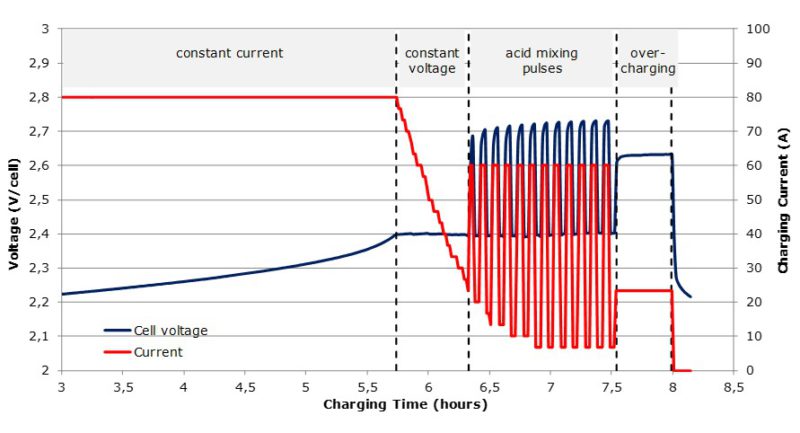

Laadcurve

- De pulscyclus is speciaal ontworpen om optimale zuurmenging en opladenseffecten te bereiken zonder overmatige belasting van de batterij.

- Het aantal pulscycli varieert automatisch afhankelijk van de batterijbehoeften. Het aantal pulsen is minder als de eerdere ontladingsdiepte laag is. Geen onnodig opladen – Geen waterverlies voor niets.

- Het mengen met zuur gaat vooraf aan de overlappende fase die nu effectiever en korter wordt.

- Het du / dt-criterium voor het einde van de lading, garandeert dat de batterij volledig wordt opgeladen met een minimale overbelasting elke keer met minimaal waterverlies.